|

Adding on to the Sacred Space

by George Shannon gjs309@magiclink.com

(Be sure and read George's column on this same subject)

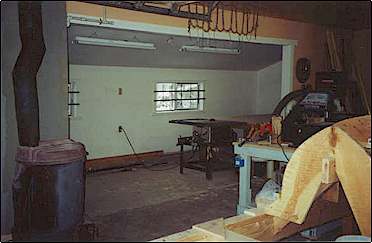

| My guess is that no matter what size of shop anyone has, it could always be

bigger. My shop (garage) was 400 sqft before I added 175 sqft this winter. Building

Microtrawler in 1999 was a stretch in that space and I could only keep it in there until

the hull was rolled over and the superstructure began. Access all around the boat was

limited and machine space was at a premium. |

Teal was a breeze and I could crank

out several at once if driven to. |

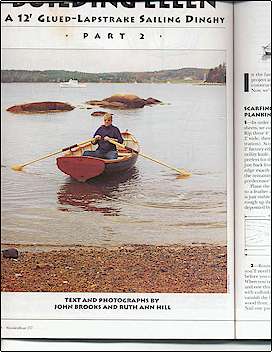

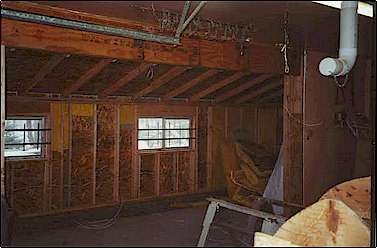

I began "Ellen", a 12 ft

lapstrake sail\row boat, recently featured in Woodenboat. |

This required a floor jig and stretched the shop to it’s

maximum capacity. I had to move some machines out in order to safely get around. After

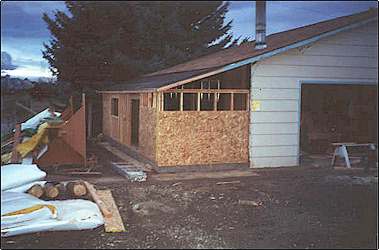

completing the floor jig about 50%, I stopped and decided to knock out a wall and add on a

cutting room to free up some floor space. |

| I have never built in the dead of winter with the ground already frozen 3 to 4

inches down. From the start I had to use a pick to dig the footings and had to keep the

ground covered and heated to pour and cure the concrete. It took over a week for curing

even after adding hot water and calcium to the mix. |

| Working with an injured arm, I had to hire my son to do all of the heavy work

and we had a good time working together. He is a far better craftsman than old Dad and

much more patient. He said he learned a lot from me, but it was really the other way

round. The framing and rough work is the fastest and most fun for me. |

| The rest of the work went easy for me because my son did all of that. The

building inspector fortunately was a helpful sort and in no way made my life miserable. I

know this is not true everywhere. |

| So far after my shoulder surgery even with one hand, I have been enjoying the

new addition. I look forward to completing Ellen over the next year or so and hopefully

other boats as well. |

(Be sure and read George's column on this same subject)

|

![]()